Your shopping cart is currently empty.

What You Don't Know Could Burn You!

Part Number:

Price:

$0.00

Ships Direct From Manufacturer

What You Need to Know

Today, gasoline tanks are frequently removed or drained to replace the fuel pump, service the fuel pump, replace the tank because of damage or to remove contaminated fuel. These services can be performed safely and efficiently if you know and follow proper procedures and use approved and certified equipment.

The purpose of this blog is to educate you on the best practices for handling gasoline and other fuels in your sevice department. Plus it will bring you up to speed on the equipment available, the certication requirements, and what that means to you and your operation.

Safety |

The biggest danger with gasoline are the vapors. They ar highly volatile. Not that gasoline spilled on the shop floor isn't a problem. But gasoline vapors are heavier than air and can travel quite a distance through the shop. And it doesn't take much to ignite them - a drop light or extension cord, or a spark from a tool, grinding or welding, or even smokeing. That is why OSHA regulations apply.

OSHA

That's right. OSHA has regulations that cover the handling of gasoline in an auto repair shop. It's OSHA Regulation 1910.106 - Flammable and Combustible Liquids.

This regulation makes it "the employer's responsibility to protect its employees from workplace hazards through providing appropriate methods of hazard control".

In other words - make sure your employees are trained in the proper methods of handling gasoline and that proper "OSHA approved" equipment is available for them to use.

Best Practices

The proper methods and/or procedures for handling* gasoline are more common sense than anything else. Let's forget the equipment for the moment and look at what we'll call "best practices".

|

Cover these procedures with your employees and make sure they are being followed.

OSHA Approved Equipment |

What is "OSHA approved equipment" and how does it benefit you?

Under OSHA regulations 29 CFR 1910-106 - OSHA approved equipment must be tested, certified, and listed by a National Testing Laboratory, based on an approval standard of that lab. These labs include Universal Underwriters (UL) and Factory Mutual (FM).

For the purpose of this guide we will refer to the "approved equipment" as a gas caddy.

Gas Caddy

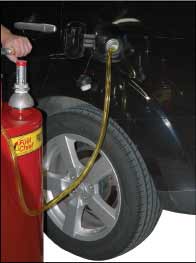

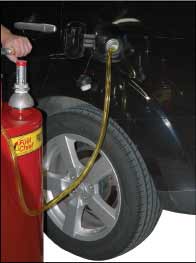

A gas caddy is a portable steel tank with a portable pump and hose attached. Its primary purpose is to safely transfer fuel from the gaoline tank; safely store the fuel during the repair process; and, safely transfer the fuel back into the gasoline tank after the repair is made.

This definition might seem over simplified but that is basically the function of a gas caddy. But there are two things to keep in mind:

Safety and Efficiency

In order to obtain FM approval, a gas caddy is tested for stability, strength, and fire safety. You certainly don't want to take 15-gallons of gasoline out of a vehicle and then worry about the tank splitting apart, or falling over or leaking.

That's why UL or FM approvals are important. It gives you the assurance that the gas caddy has been built to OSHA approved standards. The design of these gas caddies requires flame arresters on the openings, grounding cables, non sparking skids, and fill gauges. And the pump must be constructed to prevent fumes leaking from the interior of the tank.

They are vigorously tested for leakage, rupture, stability, abuse and endurance. All are tests that make safety the number one priority.

In addition to the physical tests, an examination of manufacturing facilities and quality control procedures is conducted to evaluate the manufacturer's ability to produce the product that has been tested.

How do you know if a gas caddy is UL or FM approved? Look for one of these markings on the products and owners' manual:

UL approved equipment will have this mark:

FM approved equipment will have this mark:

Efficiency |

With a gas caddy:

In some cases, not all, you can feed the hose from teh pump down the filler neck. If you can't et the hose down the filler neck then you can raise the vehicle and remove the filler neck from the tank and slide the hose into the tank that way.

the filler neck then you can raise the vehicle and remove the filler neck from the tank and slide the hose into the tank that way.

the filler neck then you can raise the vehicle and remove the filler neck from the tank and slide the hose into the tank that way.

the filler neck then you can raise the vehicle and remove the filler neck from the tank and slide the hose into the tank that way.Turn the pump handle and being transferring the fuel from the tank and into the gas caddy. The pump should transfer at a rate of 7-gallons a minute. So in 2 or 3 minutes, you are ready to go. To get the fuel back into the tank after the repair - reverse the pump direction.

Gas Caddies |

Gas caddies are available from several manufacturers in sizes ranging from 25-gallons to 250-gallons.

The "approved" equipment we are discussing here are gas caddies constructed of steel - not to be c onfused with other gas caddies available made of molded plastic. These plastic caddies do not meet OSHA requirements and are not designed for professional use - but are used by homeowners and hobbyists for transporting and dispensing small amounts of gasoline and other fuels.

When purchasing a gas caddy consider the following:FM or ULMake sure it is UL or FM approved. Both the tank and pump carry separate UL and/or FM approvals. There are steel gas caddies on the market that are not UL or FM approved - so make sure the FM or UL mark is on the tank and pump. SizeDetermine the size you need based on the vehicles you normally service. The 25 or 30 gallon gas caddies are the most popular sizes for the normal repair where fuel is removed from the tank and then returned after the repair is made. If your primary purpose is to remove fuel from the tank and store it, like in a salvage yard, then a larger capacity is probably needed. Type of PumpGas caddies are available with two types of pumps - hand operated and air operated. Your choice depends on how fast you need to transfer fuel in and out, and how much physical effort you want to exert. A goodl manual pump should transfer about 7 gallons a minute when turning at a normal rate. An air operated pump will transfer twice that amount. Again your choice depends on how much fuel you are moving and how often Type of FuelObviously you can't mix fuels in teh same tank - like gasoline and diesel - so the gas caddy you purchase must be dedicated to a specific type of fuel. If you plan on servicing ars that use E85 ethanol make sure the gas caddy is E85 compatible. Ethanol is very corrosive and can cause damage to a non-compatible caddy. It can also cause fuel contamination. FiltersTo avoid putting contaminated fuel back into the vehicle you just serviced, using a gas caddy with a filtration system is a good idea. In-line filters are standard equipment on some gas caddies. Filter its can be purchased separately as an add-on accessory. Some systems only filter the fuel one-way and others are deisgned to filter the fuel both from the tank to the caddy and from the caddy to the tank. |

Fuel Tank Adapters |

To make removing a fuel tank from a vehicle safer and easier consider purchasing a fuel tank adapter. This adapter sits on top of your transmission jack. You can strap the tank to the adapter and safely lower it to the ground.

Conclusion |

With a commitment to safety and a modes investment in equipment, you can have a safe workplace, comply with OSHA regulations, and become a more efficient and profitable business. So...

Invest in a FM or UL approved gas caddy and a fuel tank adapter - and make sure your techs know how to use them.

Make safety the number one priority by training your employees in the proper methods of handling gasoline.

Information on OSHA regulations can be found on www.OSHA.gov

Check the FM approvals guide for FM Approved Products at www.fmglobal.com

Copyright © 2009 JohnDow Industries, Inc